Traverse Standard v11.0

Manufacturing Production Scheduling Overview

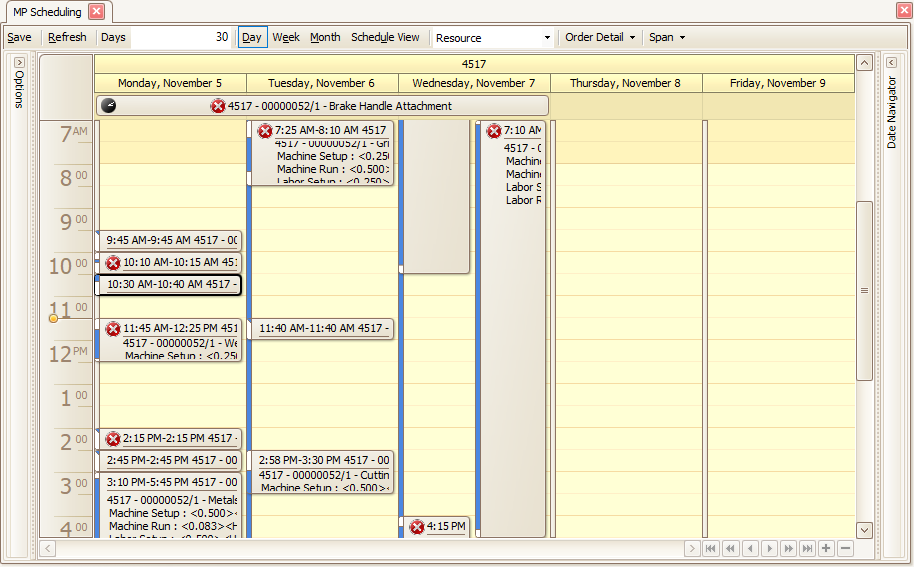

The Manufacturing Production Scheduling function is a planning tool that provides a graphical based calendar to represent different views of the production process for active production orders and/or their requirements.

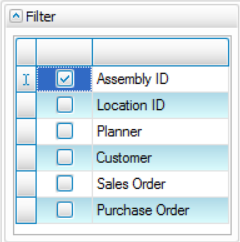

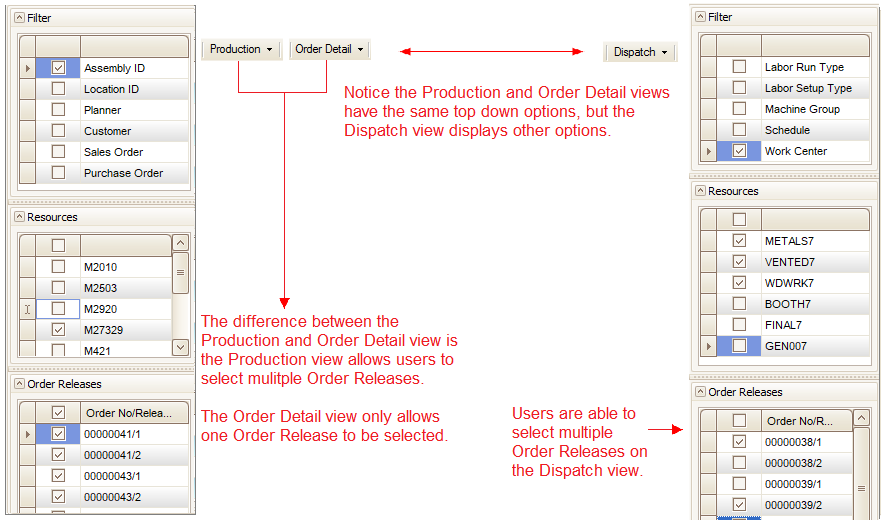

A Resource Filter includes any of the following Filter value options when Production and Order Detail types are selected:

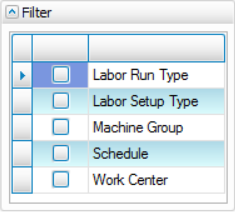

When the Dispatch type is selected, the following Filter value options are available:

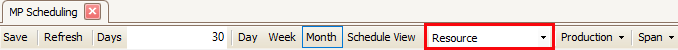

Users are also able to group calendar entries by Resource, by Date, or no grouping (None).

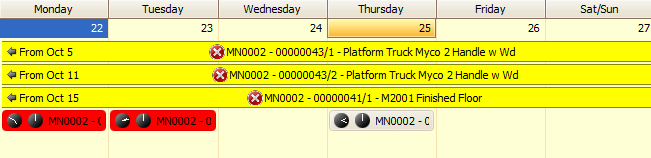

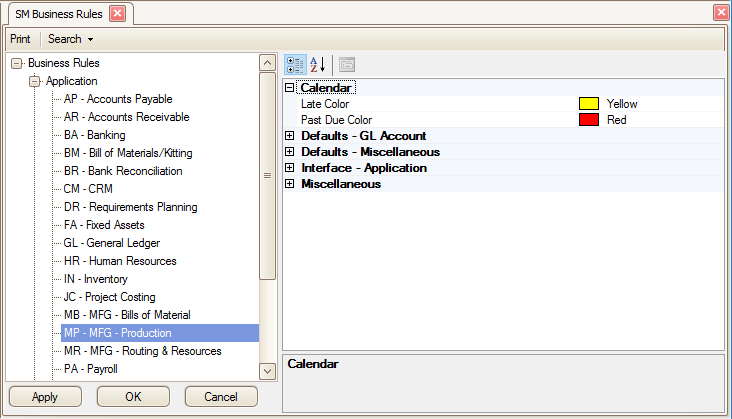

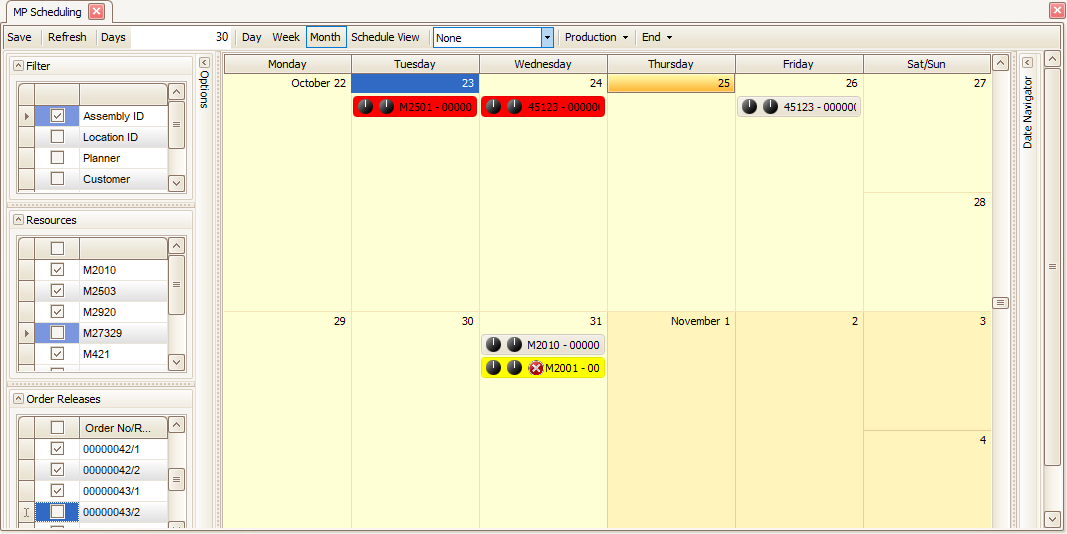

The Scheduling calendar supports drag-and-drop functionality to move production order finished goods and/or operation entries. When dates change, the system automatically adjusts the finished goods release Estimated Start and Finish Dates along with the operations Required Start and Finished Dates. The system will also change the color indicator if the release or operation is late (yellow) or past due (red).

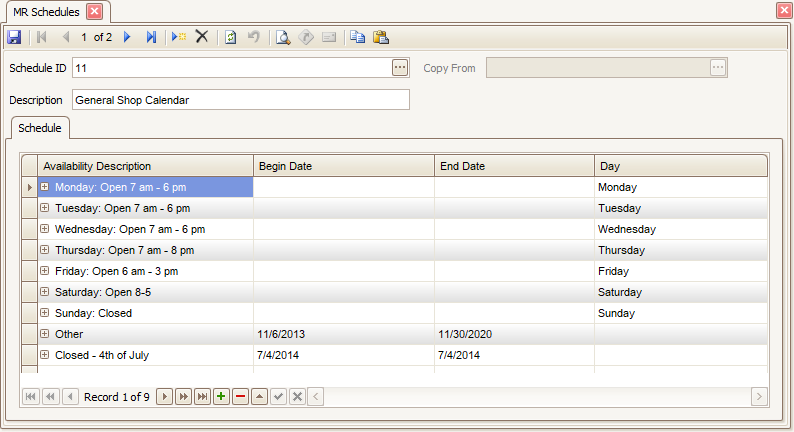

The system uses the schedules defined in the MFG - Routings and Resources Schedules maintenance screen to determine availability of resources, including daily start and stop times. If a start/end time is defined by the user, the system will utilize that time when calculating the availability of resources for the production schedule. Dates that do not have a time defined for the selected schedule will be considered days where there is no resource availability. If a requirement is subcontracted it will not be included in the calculations for the schedule, since it does not affect internal resource availability.

If you assign multiple operators to an operation, the scheduler will divide the total labor required by the number of operators. The greater of machine time or labor time (divided among multiple operators) will be used for scheduling. See the Multiple Operator Overview for more information.

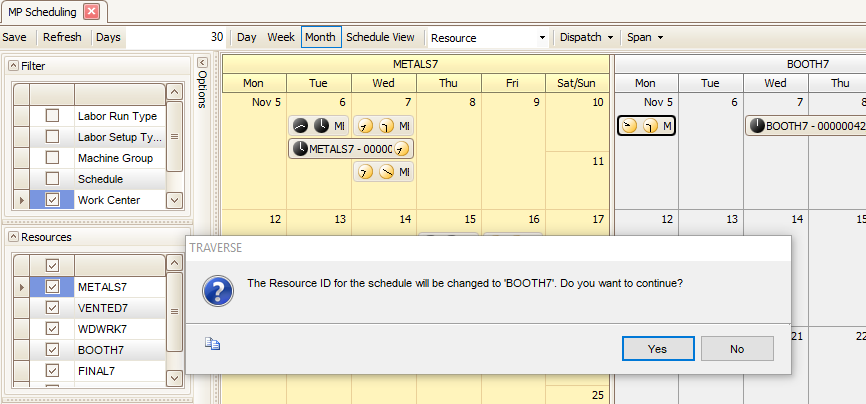

Users are also able to move entries from one resource to another when using the Dispatch type view. After selecting Yes to continue, the entry will be moved to another resource type. Then when closing the screen, the system will ask “Save changes and close?”. Select Yes for the changes to take effect or No to disregard any movements.

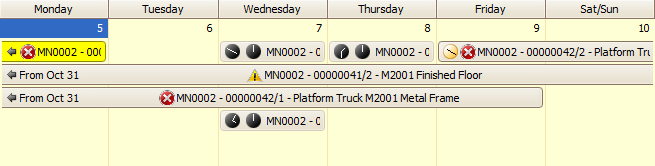

The calendar includes color coded entries that are based on the following criteria:

- Past Due (Red): Current Session Date is after the Finished Good’s Estimated End Date.

- Late (Yellow): Current Session Date is after the Finished Good’s Estimated Start Date and there is no activity for the production order/release as of the Estimated Start Date.

Note: Activity for any requirement of the production order release as of the estimated start date qualifies as progress to defer the “late” status.

If a process is scheduled to start on Monday, it cannot be “Late” until Tuesday. If there is no activity recorded on Monday, the process will always be listed as “Late”; regardless of the activity recorded on any days after Monday.

- Default Calendar Color: Does not meet special criteria for display colors.

Users are able to change the default colors in System Manager | Company Setup | Business Rules – Manufacturing Production under the Calendar heading.

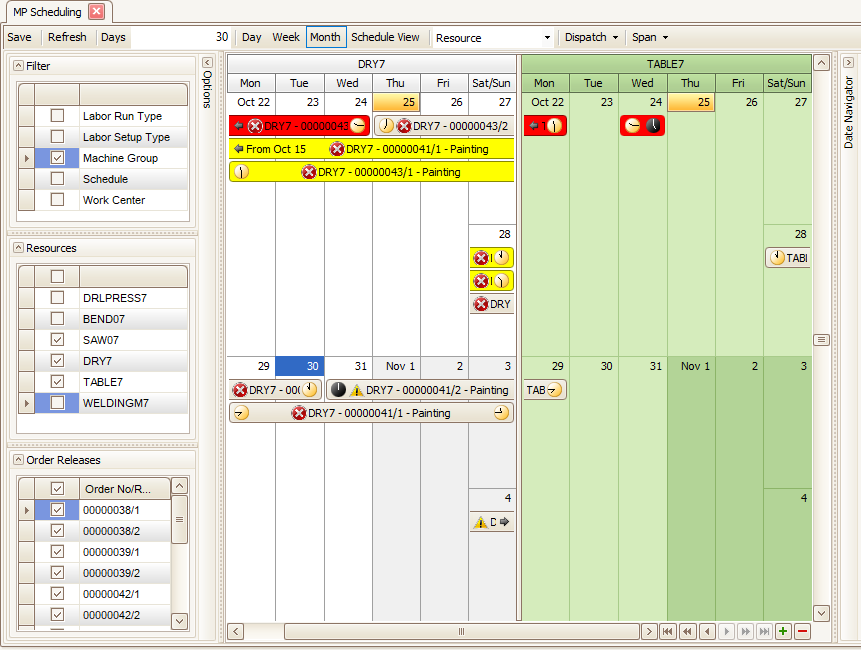

Clock Face Icons

In some views, analog clock face icons will display. These icons give you a visual indication of the start and stop times for that production order. A yellow clock face indicates AM, and a black clock face indicates PM.

![]() These icons indicate the operation is scheduled to begin at 9:30 AM and end at midnight.

These icons indicate the operation is scheduled to begin at 9:30 AM and end at midnight.

![]() These icons indicate the operation is scheduled to begin at 3:50 PM and end at midnight.

These icons indicate the operation is scheduled to begin at 3:50 PM and end at midnight.

Conflict Indication Icons

A visual indicator on an item identifies whether there is a conflict that affects the operation schedule.

- If all dates have sufficient time needed per resource, there is no conflict.

-

-- The warning icon indicates one or more of the dates do not have sufficient time needed.

-- The warning icon indicates one or more of the dates do not have sufficient time needed. -

-- The error icon indicates none of the dates have enough time; there is insufficient availability.

-- The error icon indicates none of the dates have enough time; there is insufficient availability.

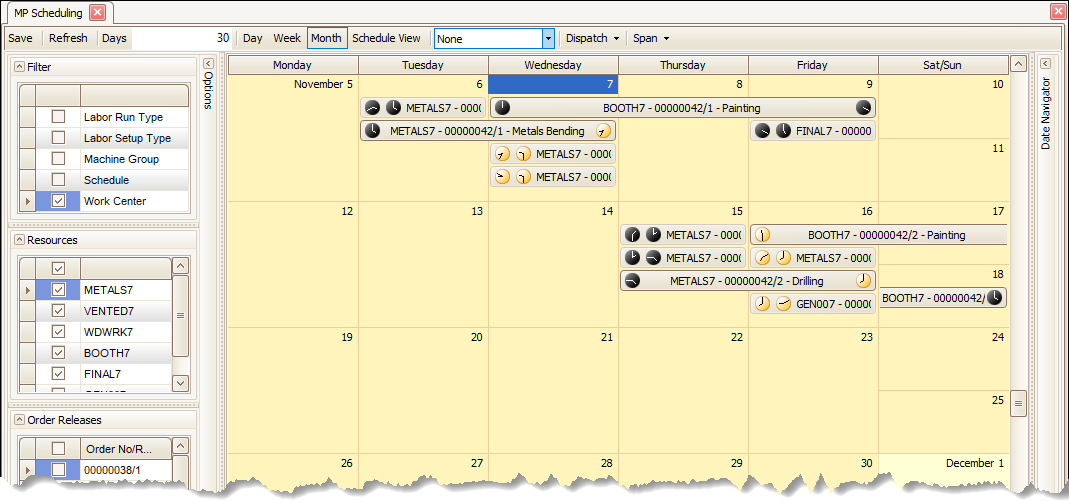

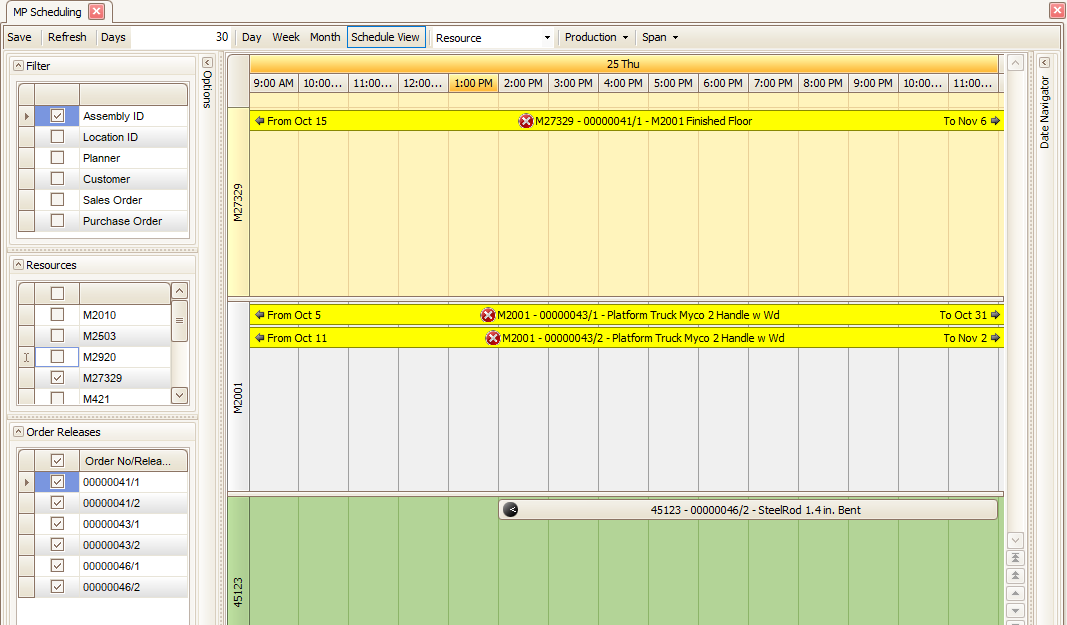

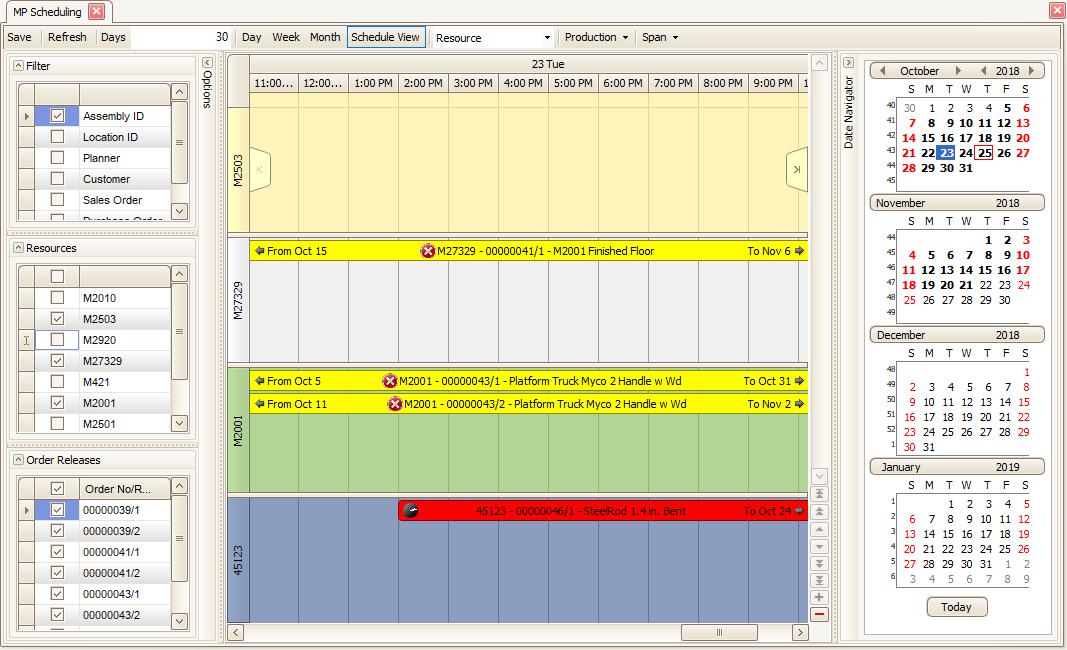

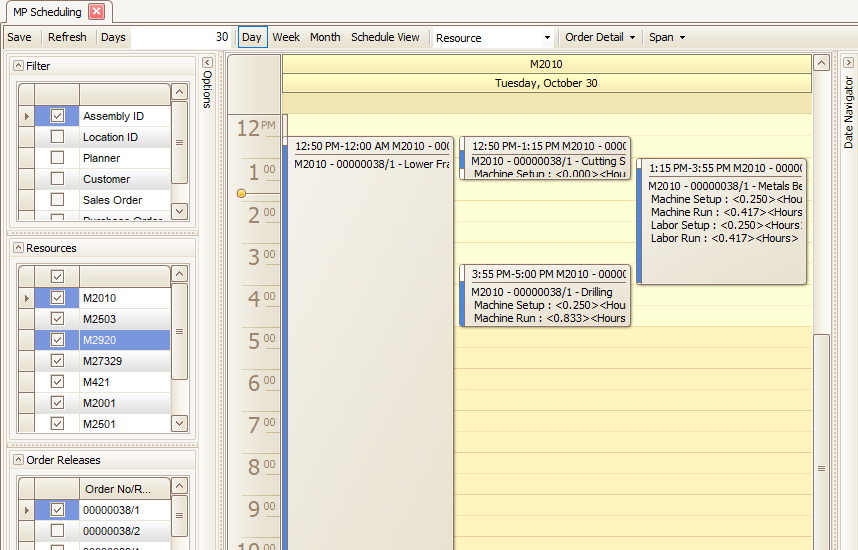

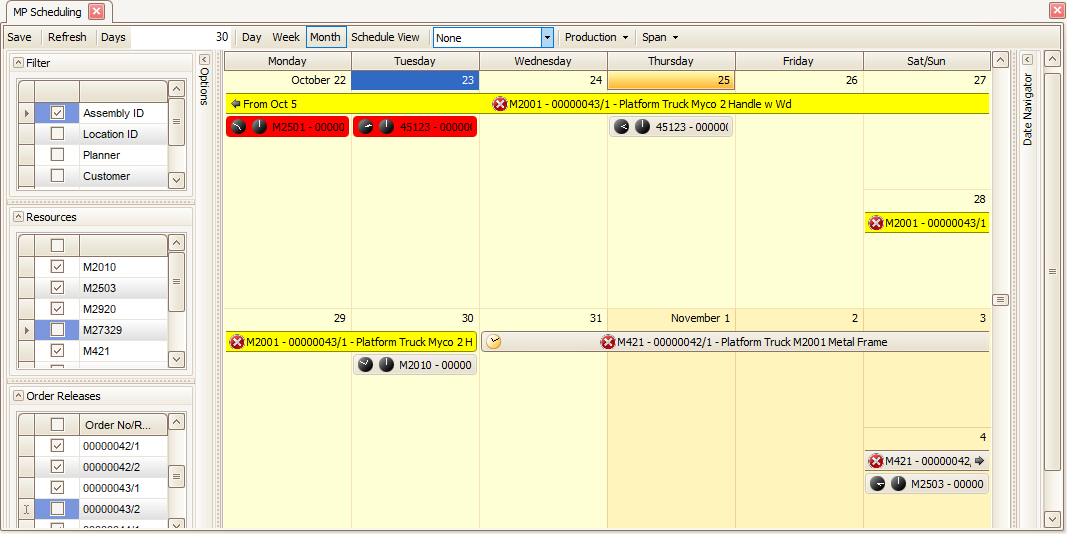

The toolbar offers options to view the calendar by Day, Week, Month, or a Schedule View. By default, the system loads the Schedule View and does not load data until the user selects filter options.

A Days span option allows you to manage the number of requirements the system will display, that is, the volume of data processed. When you enter a number of days (span of days), only requirements of valid orders within that span (from the current date forward that number of days) will be included for display and evaluation.

Grouping options of None, Date, or Resource are available to help manage the display of calendar information.

After selecting a resource Filter option, the system defaults the grouping to 'Resource'. Users are able to switch to 'None' or 'Date' at any time.

When the value of None is selected, there is no grouping on the calendar.

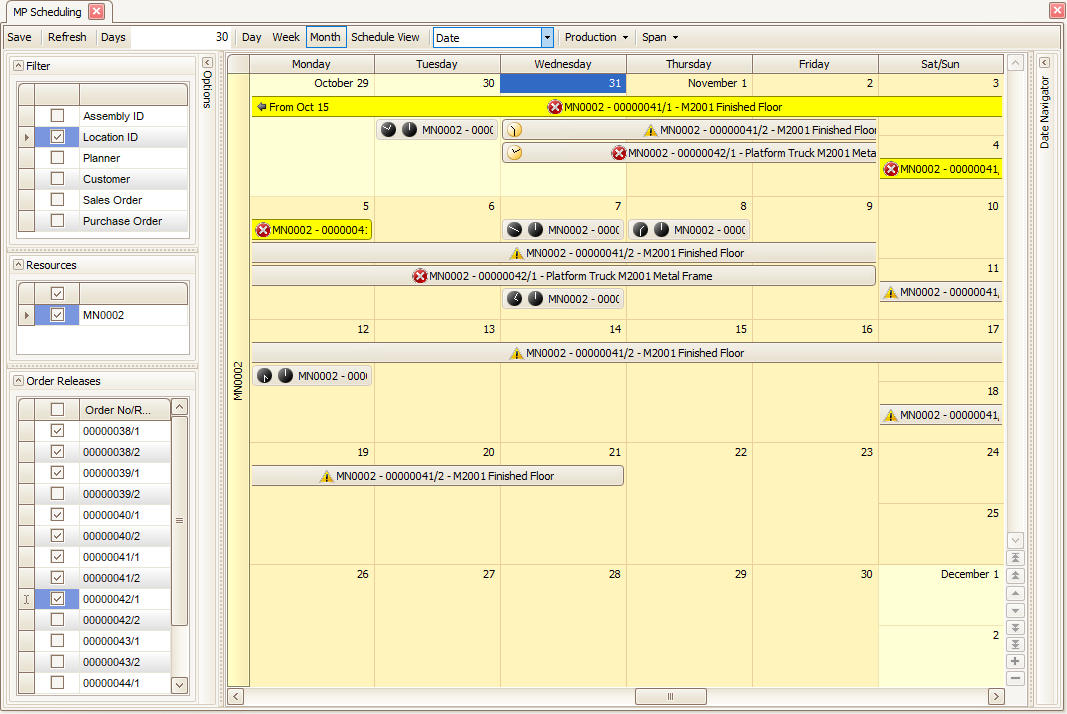

Using the Month, Date, and Production settings is another way to view filtered information.

When Resource is selected, information is displayed by the value selected under the resource Filter.

Users have the option to display information by Production, Order Detail or by Dispatch.

The Production type displays a top level overview of Production Order/Release information. The dates used for the Finished Good’s calendar view is the Estimated Start and Finish Dates.

Caption Identifier = The ID of the selected resource Filter value, the Order/Release Number, and Description of the specific Requirement

Past Due = Current Session Date is after the Estimated End Date

Late = Current Session Date is after the Estimated Start Date and there is no activity for the order/release as of the Estimated Start Date

The Order Detail type displays all operation(s) for the finished good for a single release of an order.

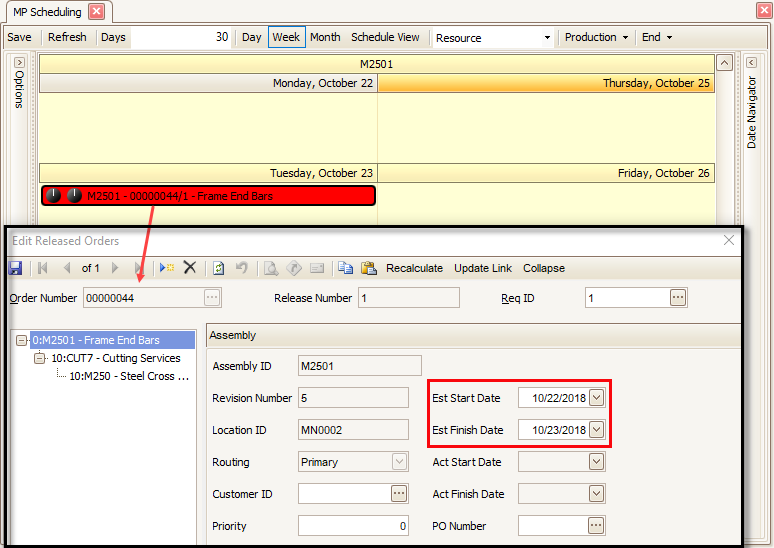

The operation dates are based on the Required Start and Finish Dates. If these dates need to be adjusted, it must be done by editing the finished good’s Estimated Start and Finished Dates in Edit Released Orders.

Caption Identifier = The ID of the selected resource Filter value, the Order/Release Number and Description of the specific Requirement

Past Due = Current Session Date is after the Estimated End Date

Late = Current Session Date is after the Estimated Start Date and there is no activity for the order/release as of the Estimated Start Date

The Dispatch type displays subsets of a given requirement type. Labor Run and Labor Setup can be different for a single requirement. Users are able to change the filter type and upon saving, the system will recalculate any child requirements.

Caption Identifier = The ID of the selected resource Filter value, the Order/Release Number and Description of the specific Requirement

Past Due = Current Session Date is after the Estimated End Date

Late = Current Session Date is after the Estimated Start Date and there is no activity for the order/release as of the Estimated Start Date

Individual entries on the calendar will be presented as an “End” point or “Span” of time for the date range associated with the entry.

Span displays continuous entries for the full date range of the given entry from start to end.

End point displays a single day entry on the end date of the entry.

When viewing the Scheduling calendar, only production orders with an active order/release status are displayed. Orders/releases that have not been released (New, Planned, Firm Planned) into the production process or have already been finished (Completed) are not included on the calendar.

Users are able to double click and drill into a calendar entry to make a change to the finished good release information within the Edit Released Orders function, which is only available if users have permission to this function. Upon making changes, users must save an order for the changes to take effect.

Bulk Lead Time (BLT) for each requirement is used to evaluate the time required to complete the task based on the Estimated Finish Date for the entire production order. The BLT is compared to the schedules associated with each operation to determine the earliest date that can satisfy the time required for the process. The evaluation only considers that time available on the given date, it does not consider the start, stop or breakdown of the individual time slots.

Depending upon the schedules used by the order/release, it may not be possible to relocate the requirement as requested. For these cases, the order/release will be moved so that the requirement is placed on the first available date prior to the requested date.

Scheduling Process for a Manufacturing Production Order

In the following example, under Manufacturing Routing and Resources | Setup and Maintenance | Schedules, a single Schedule ID is set up for weekdays Monday thru Saturday.

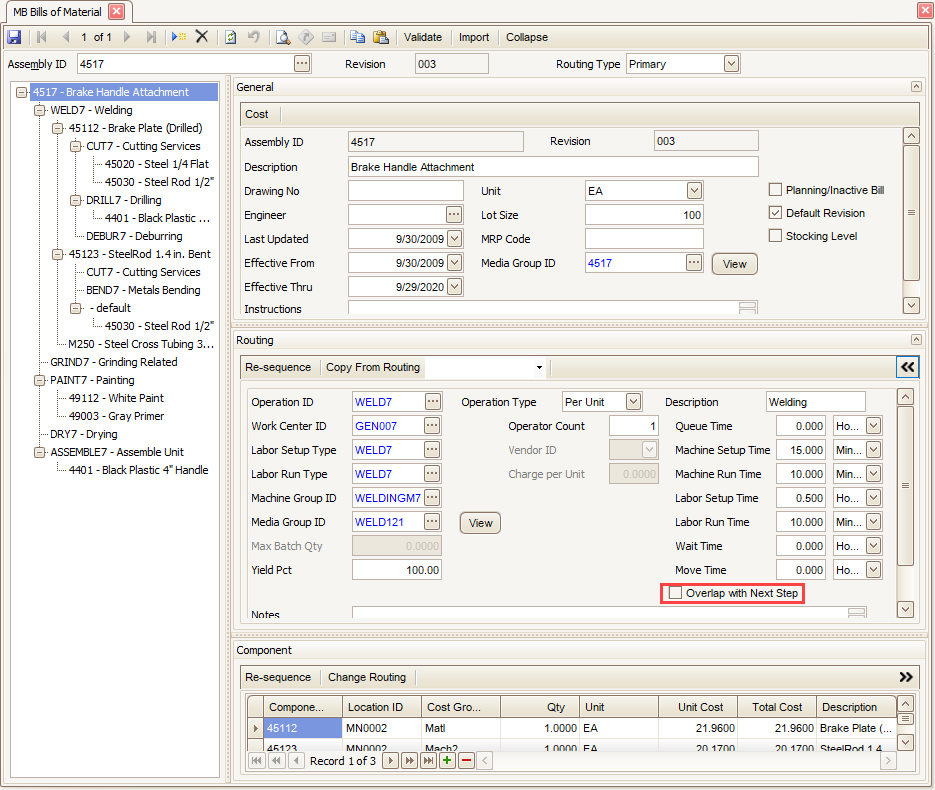

In the MFG - Bills of Material | Setup and Maintenance | Bills of Material screen, the Assembly ID we will use has multiple consecutive routing steps with no steps set to Overlap with Next Step. All steps include setup and run times.

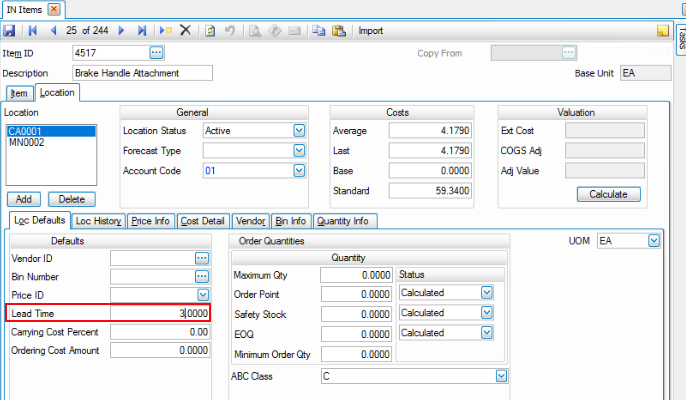

Under Inventory | Setup and Maintenance | Items, the Lead Time is set to 4.

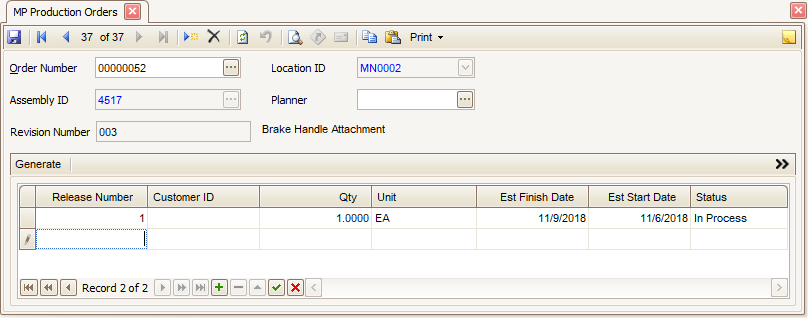

A simple Production Order is entered for Assembly ID 4517 with an Estimated Finish Date of 11/9/2018. The system then calculated the Estimated Start Date to be 11/6/2018.

Select Generate to release the Production Order.

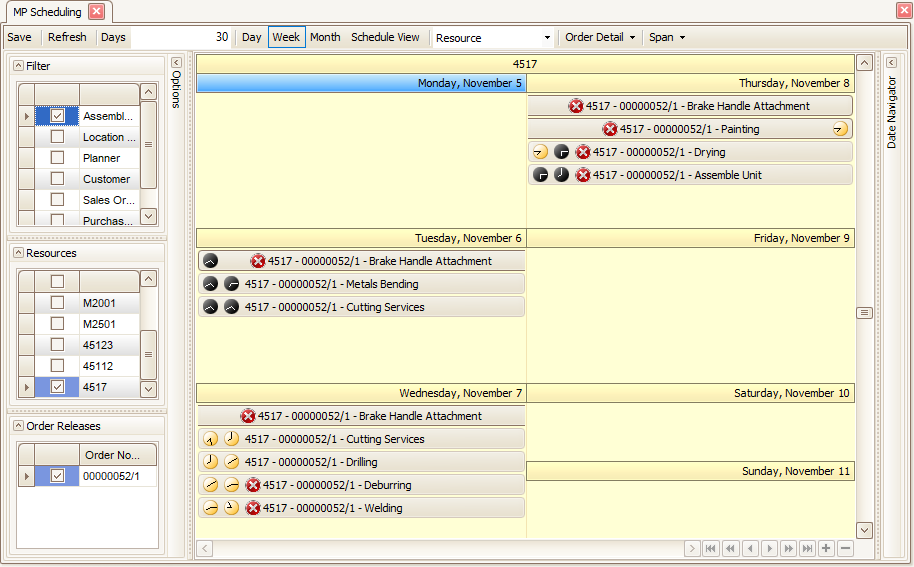

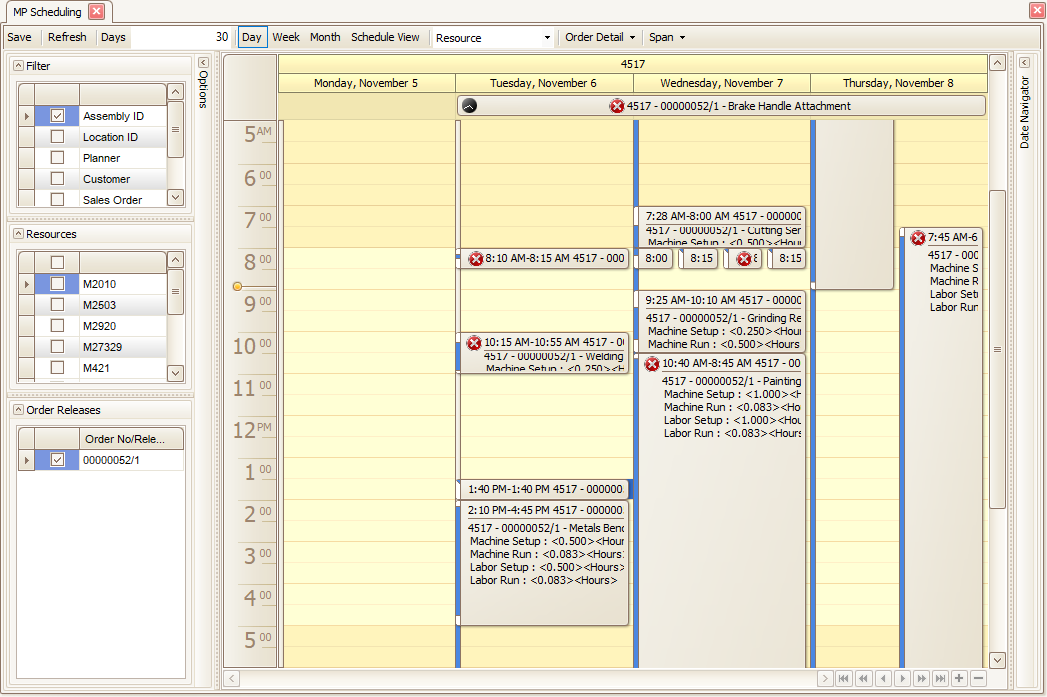

Now in Manufacturing Production | Interactive Views| Scheduling, under Type, Order Detail was selected. The resource Filter is set to Assembly ID, Resources equaled 4517 and Order Releases equaled 00000052/1.

Notice the Estimated Start Date calculated to be 11/6/2018 based on the 11/9/2018 Estimated Finish Date entered. So when viewing the calendar with the option set to Span, the production order will span over these dates.

From this setup we can determine for a finished good to be available on the Estimated Finish Date, the first routing step must start three days earlier.

Finished Good (4517) Estimated Finish Date: Thursday

Metals Bending routing step Required Date/Start Date: Teusday --> Finish Date: Tuesday (Notice the black clock faces indicating the process starts and finishes in the PM)

Cutting Services routing step Required Date/Start Date: Tuesday --> Finish Date: Wednesday (Notice the black clock faces indicating the process start/end on Tuesday in the PM, and the yellow clock faces indicating the process start/end on Wednesday in the AM. This may be due to the scheduled day ending on Tuesday before the step is complete.)

Drilling, Deburring, Welding routing steps Required Date/Start Date: Wednesday --> Finish Date: Wednesday (Notice the yellow clock faces indicating the processes start/end on Wednesday in the AM.)

Painting, Drying, Assembly routing steps start/finish Thursday, with clock faces indicating start/stop times.

You can view additional details, as well as the schedule in alternate layouts by changing the view for the schedule screen.

You can drag and drop each operation (routing step) into other time slots or days. Use the Refresh button to make those adjustments. One you are finished making changes, use the Save button at the top of the screen.

Moving any of the routing steps initiates a change in the Estimated Finish Date of the Finished Good followed by a recalculation of the Required Dates for all of the child and sibling requirements. If Deburring and Welding are moved to Tuesday, each of the routings would then be adjusted by the recalculation of the requirement dates as required:

If you move the parent production order so it starts 1 day earlier (Monday), the estimated finish date would be Wednesday and each of the routings are recalculated as required to meet the estimated finish date.

Note: If the schedule used indicates the company is not open on weekends, the dates will be adjusted accordingly.

Considerations regarding Scheduling:

- The finished goods entry does not include time, and is expected to be "finished" and available at the beginning of the Estimated Finish Date of the release. Depending on the schedule used for each operation, Finished Goods may appear to block more time than necessary (extend past the last process).

- The release/requirement recalculation process evaluates the effective time required for each operation as part of the entire production order. It then works backward from the estimated finish date, evaluating the time available on the schedule associated with each operation to determine when it needs to start.

- When you display the Span of time for an operation, the scheduling calendar will block the time from start to finish. If the operation extends past the end of the day for the given schedule, the block will continue to the beginning of the next day. Since the date/time evaluation is processed backward, the example of a 4.55 hour operation that starts at 4:15 pm would be evaluated as needing to start at 4:15 pm of the prior day in order to be available at 8:50 AM. It would need to extend into the prior day in order for the schedule to have time available to complete the process.

- Holidays and other "down time" are included in the respective schedules used for each operation. The lack of time available will result in the operations being moved to bypass the dates that are unavailable. The specific dates that are unavailable in a given schedule definition are not listed on the display, since a given production order may combine multiple schedule definitions.

- The clock icons represent the start or stop time for the item on the calendar depending upon the current view. It will toggle between the clock icon and text when the times do not fall on an even break of the current timescale (15 min, hourly, etc).

- If you assign multiple operators to an operation, the scheduler will divide the total labor required by the number of operators. The greater of machine time or labor time (divided among multiple operators) will be used for scheduling. See the Multiple Operator Overview for more information.